PlasmaSolve

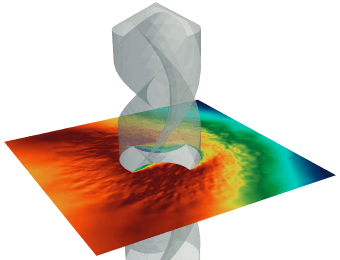

PlasmaSolve is a team of subject matter experts in plasma-powered technologies and materials science. Our mission is to create reliable and faithful digital twin models for these cutting-edge technologies. We achieve this by synergizing physics simulation, chemistry simulation, machine learning, data mining, and material characterization.

At PlasmaSolve, we specialize in helping businesses improve their PVD, PECVD, and ion source equipment. We have extensive experience in developing new processes and retrofitting existing equipment to meet evolving industry needs. Our team’s expertise also extends to simulation-guided design of other plasma sources, such as gas conversion reactors or satellite electric propulsion systems.

MatSight

PlasmaSolve started as a consultancy company that specializes in plasma-powered technologies and materials science. As of 2023, we are expanding our services to include the development of highly specialized plasma simulation software called MatSight. The first cohort of PlasmaSolve’s MatSight Apps have already been delivered to early-adopter companies and you will soon be hearing more about this innovative software tool..

Applied Research Grants

Although public co-funding comprises only a minor portion of our annual turnover, it is a vital resource stream that helps us develop new, cutting-edge simulation tools for PVD, PECVD, and ion sources.

IraSME FastPIMS (2023-2025)

Partners: Fraunhofer IWM, Aurion GmbH

Project “FastPIMS: Simulation driven Fast switch match system for pulsed rf/HiPIMS plasma applications”, reg.no. CZ.01.01.01/01/22_002/0000106 is co-funded by the European Union. The aim of the project is to develop a global RF and HiPIMS sputtering model that will allow the sputtering process of oxide coatings to be configured and customised for specific users and their applications without the need for a lengthy testing process.

TAČR OPTIMISM (2020-2025)

Partners: Masaryk University, SHM s.r.o.

Scope: PlasmaSolve is coordinating this research project, where we are implementing computationally efficient coater-scale plasma models and demonstrating their efficiency on ta-C and AlCrN coatings grown by high-power magnetron sputtering. Another important aspect of the project is absolute measurement of sputtering yields in various contexts (metalic, poisoned, …)

TAČR SILAS (2023-2025)

Partners: SpaceLabEU SE (coordinator), Brno University of Technology

Scope: PlasmaSolve is developing a digital twin model for a unique ECR ion source. The key characteristic of the ECR ion source is the ability to operate at very low pressures, as low as 20 mPa. The primary application of the device is air-breathing satellite electric propulsion but a laboratory version of the device is also envisioned.

M-era.net MIST (2020-2021)

Partners: Université de Namur (coordinator), AGC Plasma

Scope: The project coordinated by UNamur aimed to create a Multi-scale simulation toolbox for PECVD processes. The efficiency and accuracy of the simulation toolbox combining PlasmaSolve’s and UNamur’s models was illustrated on the example of the AGC’s novel hollow cathode technology.

Horizon 2020 PlasmaJetPack (2019-2022)

Partners: COMAT (coordinator), OHB Sweden, CNRS Icare, Bundeswehr Uni München CNRS Laplace, TAS France

Scope: COMAT is a developer of a disruptive solid-propellant vacuum arc thruster for satellites. PlasmaSolve contributed to their ambitious goal by numerical modeling of the vacuum arc and its contraction under magnetic fields. In the process, PlasmaSolve has significantly improved its vacuum arc simulation capabilities and created a trustworthy database of vacuum arc erosion rates for various cathode materials.

Scientific Papers

As time-consuming as it is, we try to publish our research regularly as a way of paying back to the academic community that we are learning a lot from!

K. Tomanková et al. Simulation of a hollow-cathode PECVD process in O2/TMDSO for silicon dioxide deposition – Cross-code validation of 2D plasma model and global plasma model. Surface Coatings and Technolgy 474 (2023). Open-access.

A. Roštek et al. Simulating ion flux to 3D parts in vacuum arc coating: Investigating effect of part size using novel particle-based model. Surface Coatings and Technolgy 449 (2022)

K. Mrózek et al. Global plasma modeling of a magnetized high-frequency plasma source in low-pressure nitrogen and oxygen for air-breathing electric propulsion applications. Plasma Sources Science and Technology 30 (2021). Open-access.

M. Kubečka et al. Predictive simulation of antenna effect in PVD processes using fluid models. Surface Coatings and Technology 379 (2019).

R. Rudd et al. Plasma gas aggregation cluster source: Influence of gas inlet configuration and total surface area on the heterogeneous aggregation of silicon clusters. Surface Coatings and Technology 364 (2019)

R. Rudd et al. Manipulation of cluster formation through gas-wall boundary conditions in large area cluster sources. Surface Coatings and Technolgy 314 (2016)